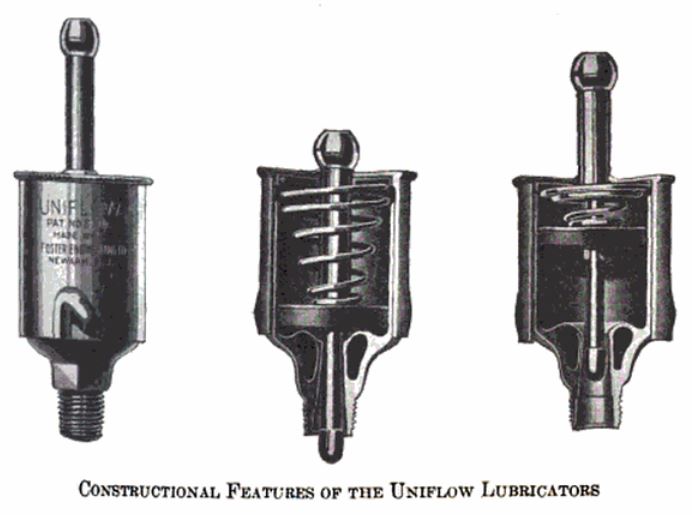

Uniflow Lubricator

books.google.com - National Engineer Magazine

National Engineer for February, 1923 Page 81

Power Plant Equipment

Uniflow Lubricators

For Automatically Feeding Grease

to Engine and Machine Bearings

. . Have a Number of Unique Advantages.

Engineers familiar with the various types of grease cups, ranging from the plain compressing cups, requiring frequent attention to the so-called automatic (spring actuated) grease cup, will readily recognize and appreciate the value of Uniflow Lubricators. The ordinary spring compression cup is not automatic beyond the point of adjustment set by the engineer. The regulating screw located in the shank leaves much to be desired because the operator has no means of knowing how much to close the orifice without removing the cup, and also because it is dangerous to attempt to regulate the outlet when the machinery or engine is in motion. Governor lubrication is one of particular importance, as a well lubricated governor means close regulation, with resultant economy in operation, as well as reducing the possibility of load fluctuating, dragging or racing the engine. Grease cups on inertia governors cannot be touched while the engine is running, and for this work, Uniflows have a great advantage. Engineers who attempt to regulate the ordinary spring compression cup by adjusting the regulating screw will find that the cup will stop feeding before the stroke is completed. Uniflow Lubricators control the outlet automatically so that the outlet area is increased in proportion to the weakening of the spring.

This regulation — measured in thousandths of an inch — is more positive, sensitive and accurate than is possible to attain by human control. The Uniflow control makes each size of Uniflow cup in capacity and service equal to any ordinary spring actuated cups at least three times its size according to claims of the manufacturer. Compared with oil cups, Uniflows have a number of advantages. Uniflows are being used with satisfactory results on speeds up to 2,300 rpm. on planishing machines, grinders, etc. High speed bearings on textile machinery, to slow speed mills or rumblers in foundries have been equally and satisfactorily lubricated. Loose pulley and clutch lubrication — usually a source of trouble, are taken care of with ease. Punch presses, and metal working machinery operating on production basis have shown to advantage with Uniflow lubricators.

Lubricating the valve gear of large Corliss engines is another interesting service rendered by Uniflow Lubricators.

Uniflow Lubricators are adaptable to any type of standard bearing, wherever an oil cup or grease cup is used. They will work in any position. Centrifugal motion does not prevent them from discharging contents, and they are operating on speed up to 2,300 rpm. These cups are manufactured by the Foster Engineering Co., 109-117 Monroe St., Newark, N. J.