Liberty V-12 Maintenance

THE BATTERY

Click here for recommended Liberty battery Maintenance

- - - - - - - -

The possibility of trouble can be reduced to a minimum by the exercise of care in the daily routine inspection, and by cleanliness throughout. The detailed instructions for the maintenance of the battery should be carefully followed, as the amount of electrolyte is so small that there is no margin for neglect. The distributor heads should be removed daily, and the brush tracks wiped with a soft rag and a little petrol- At the same time the contact breakers should be dusted with a soft brush, and once a week the lever pivots should have a drop of oil. Otherwise, practically no attention is needed, and the contacts should run for many hours without requiring adjustment.

DAILY ROUTINE

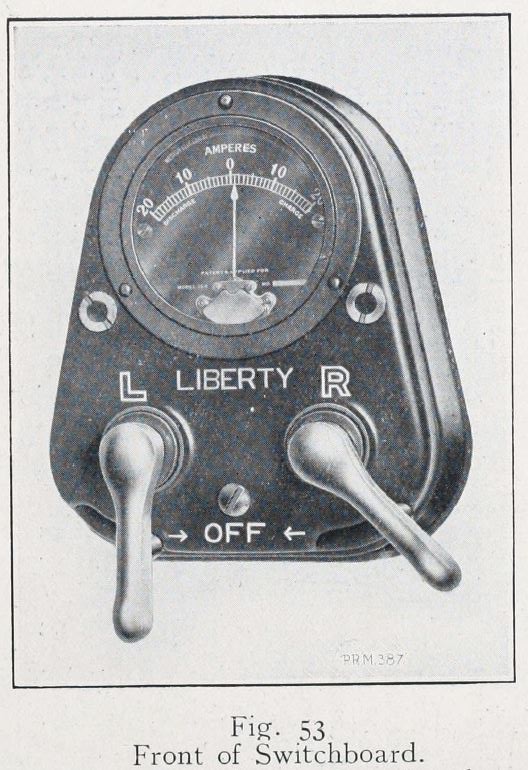

1. Take the voltage of the battery before each day's flying. On open circuit—that is to say, with both ignitions switched off—the voltage should not be less than 8 volts; with one ignition switched on, and the ammeter showing a discharge of from 4 to 5 amperes, the reading should be not less than 7 1/2 volts. Should the Voltages be lower, a freshly charged battery should be fitted.

2. Remove and clean the plugs, and set their gaps to 0.015 in., renewing any plugs that appear to be of doubtful soundness.

3. Remove the distributor heads and examine the contact breakers. The gap should be between the limits of 0.010 and 0.013 in., and the points should meet squarely.

4. Clean the carbon brush tracks of the distributors with petrol on a piece of cloth. Do not use any abrasive material.

5. Run over all leads, especially those on the engine, examine— for deterioration from oil or burning, and see that all terminals are tight.

6. Before starting the engine, switch on each ignition system separately, and note the ammeter readings, which should be approximately equal. It may be necessary to turn the engine a few degrees backward, in order to bring the main contact breakers to the closed position before the full current can flow. Should one system show no discharge reading, there is a break in the circuit, probably due to a loose terminal or very dirty contacts. Should one show an excessively high discharge, there is a partial short circuit somewhere. To detect a short in a coil as distinct from the wiring, change over the primary leads to the distributor heads.

7. Immediately the engine stops, put both ignition switches to the OFF position.

WEEKLY ROUTINE

1. Flush the battery as already detailed, and correct the acid density if necessary. Wipe the battery dry and clean from acid, and smear a little vaseline on the terminals before replacing it. Wipe out the battery box.

2. Remove the dust cover from the generator brush gear, dust the commutator, etc., and, if necessary, clean with petrol. See that the brushes are in order, and put a few drops of thick oil on the bail bearing at the top of the armature spindle.

3. Clean out the contact breakers, and put a drop or two of oil on the pivot bearing of each lever. Check and readjust the points if required. The amount of slack in the driving coupling should not allow of more than about 1/16 in. of play at the end of the distributor rotor.

MONTHLY ROUTINE

1. Let the weekly clean-up and inspection be, if possible, more thorough than usual.

2. Open out the switch, clean all contacts, and put a little vaseline on the track. Inspect the resistance coils.

3. Inspect and clean the voltage regulator. The gap between the contacts should be from 0.005 to 0.007 in. when the blade is pressed down upon the stop-pin. Work a drop of oil into the pivot bearing.

CHAPTER V.

Running Instructions.

MAXIMUM R.P.M.

The army type of Liberty engine has a high compression ratio, for the purpose of obtaining a high power output at altitude: it must never be run all out near the ground. Pilots and mechanics should carefully note the following r.p.m. limits :—

Maximum speed "running up" on the ground, 1,400 r.p.m.

Maximum permissible speed flying at ground level, 1,500 r.p.m.

Normal full speed at or above 6,000 ft.-1,650 r.p.m.

Maximum permissible speed at or above 6,000 feet.- 1,750 r.p.m.

If a suitable propeller is fitted, it is practically impossible to exceed 1,400 r.p.m. in ground tests. The naval model has a lower compression ratio, so that its maximum speed, irrespective of height, is 1,750 r.p.m.

PRECAUTIONS WITH A NEW ENGINE

It is highly inadvisable to run a new engine at all hot, as there is a considerable risk of "baking" the rings into their grooves with burnt oil, a mishap which can only be remedied by dismantling the engine completely. For this reason it is inadvisable to run on a weak mixture—e.g., by testing the altitude control for more than a few seconds at ground level.

FILLING WITH OIL

The recommended oil is Vacuum Mobiloil BB, the average consumption being eight to twelve pints per hour. A safety allowance of three gallons over and above the calculated consumption for an intended flight must be provided. When the engine is stopped after a flight, about a gallon of oil will slowly drain down into the sump. The scavenge pumps have a greater capacity than the pressure pump, and this gallon will quickly be returned to the tank when the engine is next started. It is therefore necessary to allow ample clearance in the tank when replenishing. As allowance must further be made for frothing and expansion, clearance should be left in the tank for about 1 1/2 gallons of oil, whenever the sump has not been drained.

In winter the tank should be replenished with heated oil, unless facilities are available for keeping the engine warm whilst in the hangar.

The main thrust bearing must be filled with oil by means of an oil can before each flight. Mechanics should realise that the thrust housing will hold a good deal of oil, and that the race cannot run dry during a long flight if the housing is filled.

COOLING SYSTEM

A plug beneath the lower delivery connection on the pump permits all the water to be drained in frosty weather. In refilling the cooling system, it is advisable to raise the tail of the aeroplane, so that the system will fill from the bottom upwards. Otherwise air may be trapped, when the circulation will be imperfect, and the machine will start on its flight with less than the full complement of water.

OIL PRESSURE

After first starting up, therefore, if the pressure begins to fall, and finally becomes constant at about 25-30 lbs. at 1,650 r.p.m., when the oil has warmed up, the circulation is almost certainly correct.

In very cold weather the safest method of warming up the oil is to run the engine for several spells of two or three minutes each, switching off between spells, so that heat can reach the base chamber by conduction. The camshaft is remote from the pump, and may be the last component to receive proper lubrication, when the circulation is very sluggish. Under such conditions one of the lids may be removed from the camcase, and hot oil poured in.

When the engine is accelerated towards its maximum r.p.m., the pressure gauge should register not less than 25-30 lbs.

A WARNING ABOUT THE SWITCHES

The Liberty engine is liable to be started accidentally, when it is warm or has just been doped, ready for starting. The type of ignition employed affords a very good spark: any rapid switching on and off produces a crude form of make and break, and may lead to sparking at the plugs. Special care should therefore be taken to see that nobody is within reach of the propeller when the switches are operated.

One switch only must be on contact at starting: if both switches are "o0 " during starting or slow-running the heavy rate of discharge will run down, and will injure the battery. Needless to say, both switches must be kept in the off position when the engine is out of use, or the battery will run down. (See pp. 68 and 93.)

STARTING THE ENGINE

Owing to the excellence of the spark at low speeds, the engine is easy to start, despite its size. It is doped via the compression cocks above the inlet manifolds or by means of the doping pump in the cockpit.

ONE distributor switch is then put on contact, the ignition being fully retarded, the throttle lever in the be drawn off by either of two methods, viz.:— minimum position, and the altitude control shut. On the propeller being swung or the starter (if any) being operated, the engine should start. (The Americans usually pull the propeller over, compression by means of three mechanics who link hands in line, the left-hand man pulling the propeller with his left hand, the centre man pulling on the right-hand of the man at the propeller, etc.) As soon as the engine fires, the ignition should be fully advanced, and the second distributor head switch put to "contact." The engine cannot fire backwards, as auxiliary contact-breakers cut out the ignition when a backfire occurs.

AFTER STARTING UP

Warning is given above against accelerating before the oil is sufficiently fluid to circulate properly. The larger the quantity of oil in the tank, the longer will be the delay. A satisfactory oil temperature is 40° Centigrade, and this may not be attained for ten minutes in cold weather, if a supply of five gallons is carried. When the oil is circulating properly, the engine may be accelerrated for a revolution test up to 1,400 r.p.m. Make a revolution test on each ignition set separately.

Should a test of the altitude control be made, the tachometer should register a drop of approximately 200 r.p.m. if the altitude control is fully opened for a few seconds with the engine running at 1,400 r.p.m. The altitude control must not be kept open for more than a few seconds at ground level, or the slow-burning mixture may cause the engine to catch fire.

SMOKY EXHAUST ON WIDE THROTTLE OPENINGS

A smoky exhaust is noticeable at or near full throttle opening in the case of engines equipped with the H.C.7 carburettor. This effect passes off as the machine climbs into a less dense atmosphere, and is apparently due to "cracking" of the oil and petrol vapour, due to the high compression ratio of the engine, the volumetric efficiency of the H.C.7, and local causes peculiar to individual cylinders, (e.g., overheated valves or pistons, carbon deposit, or uneven mixture).

The matter is not serious, as the exhaust will become clear, owing to decreased cylinder pressure, before reaching 10,000 feet. The smoke may be decreased by slightly retarding the ignition. In any case, the ignition, in flight, should be set to the point at which the engine runs best from the point of view of revolutions; and it should be noted that with its special form of ignition the Liberty engine is sensitive to its ignition control to a greater extent than occurs where magnetos are used.

This paragraph is included to prevent mechanics from ascribing the smoky exhaust to over-large jets. The standard Claudel jets (main 490 cc., pilot 200 cc.) are the smallest compatible with full r.p.m. at ground level.

AFTER THE PRELIMINARY RUN

If circumstances permit, switch off the engine after its preliminary run and acceleration tests, and carry out the following inspections :—

i. The sump and camshafts should be warm.

ii. The cylinders, water pipes, and radiators should be hot.

iii. See that the water pump is not excessively hot, indicating that the stuffing glands are too tightly packed.

iv. There must be no oil, petrol or water leaks.AFTER A FLIGHT

Take whatever precautions are locally authorised to facilitate the next start, e.g., inject a little paraffin into the compression cocks, and on to the valve stems, giving the engine one or two turns.

- Refill the oil tank, unless this job is postponed in order to use warm oil immediately prior to restarting.

- Test, and, if necessary, reset the tappet clearances.

- Overhaul all nuts.

- Fill the main thrust with oil.

- Clean the petrol filter, and, if ordered, all three oil filters.

- Examine, and, if necessary, clean or renew the sparking plugs.

- Inspect all ignition connections.

- In winter, take precautions aganst frost: in summer, replenish with water.

- Verify the condition of the ignition, especially the accumulator. Test the firing on each distributor separately. As this ignition is of a type unfamiliar in the British Services, Chapter IV. should be carefully studied.

- Refill the petrol tanks.

PERIODIC ATTENTIONS

- Cleanse the oil and petrol filters.

- Overhaul and test the ignition. (See Chapter IV.)

- Examine the high tension cables for worn or perished insulation.

- Remove and clean all the sparking plugs.

- Cleanse the carburettors.

- Examine the stuffing glands of the water pump.

- Oil the joints of all the engine controls.

LUBRICATION SYSTEM

The oil tank must have a capacity 20 percent larger than the amount of oil required by the engine for the flight endurance provided by the petrol tanks.

COOLING SYSTEM

Reserve water required in gallons:

N = Normal engine B.H.P.

H = Hours fuel capacity allowed

C = Reserve water required in gallons

C = 1 + (H * N)/1600-- end --